Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

Blog | January 28th, 2026

Cost and ESG impacts of water vs oil in Stern Tube bearings explained by Wildon Engineering, helping shipowners choose a smarter, sustainable solution.

For many vessel operators, the decision between traditional oil lubrication and modern seawater lubrication has become a critical operational and environmental consideration. As regulatory expectations tighten and sustainability requirements grow, the lubrication system chosen for a vessel’s Stern Tube bearings can significantly influence costs, compliance, and long-term performance. This shift has prompted shipowners to reassess whether oil-lubricated systems remain viable or whether water-lubricated alternatives provide a more strategic and future-proof solution.

What Are Stern Tube Bearings and How Do They Work

Stern Tube bearings support the propeller shaft where it exits the vessel’s hull, absorbing radial loads and ensuring smooth, stable rotation throughout operation. These bearings operate within the stern tube and rely on a lubrication medium to reduce friction, dissipate heat, and prevent wear.

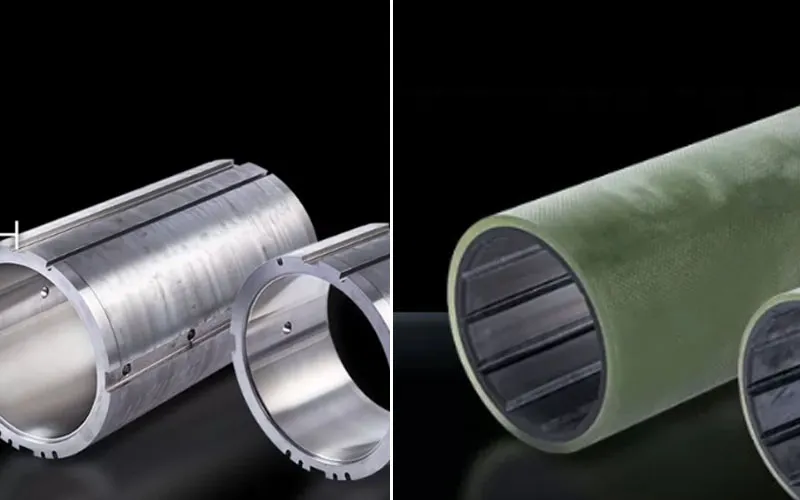

Oil-lubricated systems rely on mineral or biodegradable oils contained within sealed chambers that depend on the integrity of aft and forward seals. Water-lubricated systems instead use seawater circulated through engineered channels to create a hydrodynamic film between the shaft and the bearing surface. With modern polymer and elastomeric materials improving durability and reducing contamination risks, understanding these differences is crucial for shipowners assessing maintenance, environmental impact, and compliance requirements.

Pros & Cons — Water-Lubricated vs Oil-Lubricated Systems

The choice between water and oil lubrication involves operational, environmental, and cost-based considerations. The table below summarises the primary advantages and limitations of each system.

| Criteria | Water-Lubricated System | Oil-Lubricated System |

| Environmental Impact | No risk of oil discharge; aligns with zero-pollution objectives. | Potential for operational leaks; environmental liabilities. |

| Lifecycle Cost | Lower long-term costs with no oil purchasing or disposal requirements. | Higher ongoing costs from oil procurement and seal maintenance. |

| Maintenance Requirements | Simpler system with fewer sealing components. | Requires monitoring of seals, oil quality, and contamination. |

| Bearing Materials | Advanced polymer and elastomeric linings provide improved durability. | Metal bearings are well-established but reliant on oil integrity. |

| Cooling Efficiency | Superior cooling through continuous seawater flow. | Cooling depends on oil circulation and system design. |

| Performance Under Load | Highly reliable with proper alignment and water flow. | Traditionally strong under heavy loads; proven in long-term use. |

| Retrofit Complexity | May require structural changes and new liners. | Straightforward in vessels already designed for oil systems. |

Environmental & ESG Considerations: Why Water Lubrication Is Gaining Traction

Environmental expectations and ESG requirements are reshaping the maritime sector, making seawater lubrication a preferred option for shipowners seeking responsible operation. By eliminating oil-leak risks and aligning with modern sustainability standards, water-lubricated systems support regulatory compliance while reducing long-term operational liabilities.

Key reasons water-lubricated systems are gaining broader adoption include:

• Elimination of oil discharge risk, supporting marine-protection goals.

• Lower lifecycle operational costs and reduced waste-handling obligations.

• Favourable alignment with environmental regulations in Australian and global waters.

• Reduced the likelihood of seal failures and associated emergency maintenance.

Trusted Stern Tube Bearing Solutions Backed by Wildon Engineering’s Expertise

Selecting the right lubrication approach for Stern Tube bearings now influences operating costs, compliance, and vessel reliability. Water-lubricated systems reduce risk, lower lifecycle expenses, and enhance ESG performance. Wildon Engineering supports shipowners with advanced, environmentally aligned bearing solutions tailored for long-term, reliable propulsion.

For expert support or to discuss water-lubricated Stern Tube bearing options for your fleet, contact us today. We are ready to assist with the right solution for your vessel.

Related Blog Articles:

Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

Water Lubricated Stern Tube Bearing (EVR): Proven Technology for Smooth and Quiet Operations

Optimized by NetwizardSEO.com.au

Recent Posts

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems

- Water Lubricated Stern Tube Bearing (EVR): Proven Technology for Smooth and Quiet Operations

- Marine Spare Parts Australia: Genuine Components for All Vessel Types