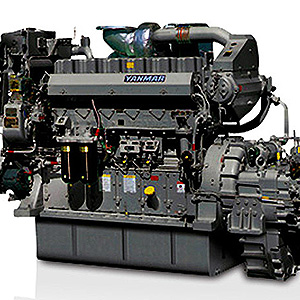

Best Tips in Winterizing Your Yanmar Diesel Engine

Blog | May 17th, 2017

Contemporary diesel engines are advanced pieces of equipment. Likewise, their fuel sources are formulated from advanced hydrocarbon blends, so that ignitable energy source won’t become a waxy mess when the winter weather exerts its arctic grip. Still, having promoted these virtues, a smart engineering team always protects his engine from the elements. Let’s adopt that same level of marine engineering diligence by looking at the best tips for Winterizing your Yanmar diesel engine.

Adopt A Step-by-Step Work Model

There’s no single miracle cure-all here, just a series of important steps. Each one must be followed to the letter, though, or your Yanmar marine engine could suffer. If damage does occur, the worst feeling would be the knowledge that this unfortunate (possibly expensive) event could have been avoided by adhering to a few maintenance tips.

Have The Oil Changed

A Yanmar diesel engine is a rugged piece of equipment, which means it can withstand punishment. You don’t want to add insult to injury, though, so replace that oil. Replace the transmission oil, the engine oil, and the oil filter with new, contaminant-free products.

Stabilise The Diesel Fuel

Modern diesel fuels are formulated to resist the cold, but a resistance feature isn’t the same as full immunity. Add a stabilising agent to the diesel as an additive. The selected fuel treatment enzyme regulates energy release, winterizes the diesel, and it generally improves throttle response. That’s a sound winter protection supplement, one that eliminates wax and water build-up.

Winterizing Your Coolant System

Water is the obvious culprit when the mercury drops. The water out on the open seas and lakes can form an icy rind along your boat’s deck, but this isn’t the biggest threat you’ll face. Down in the engine, the coolant system is faltering. Replace the coolant. Next, look at the sacrificial anodes inside the cooling system? Are they corroded? Replace these anodes if they’re fatigued. Otherwise, the metal parts in that coolant system will corrode.

General Maintenance Tips

Check the antifreeze level, the exhaust manifold, and the engine hoses. There shouldn’t be any soot or buildup of any kind on that exhaust system. Likewise, the elastomeric hoses must be inspected for bulges and softening. Moderns engineering elastomers are marine-capable, but a hard-labouring Yanmar marine engine can push these supplemental parts to their limits.

Ironically, as a fluid-cruising vessel, it’s the fluid systems that can cause the most trouble on a boat. Winter winds are blowing and icy rains are falling, so take the craft into its berth for its Winterizing inspection. Replace the fluids, when possible, then test all fatigue-prone parts, before settling down to wait for the Spring, plus a whole host of new seasonal inspection routines.

Optimized by NetwizardSEO.com.au

Recent Posts

- Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems

- Water Lubricated Stern Tube Bearing (EVR): Proven Technology for Smooth and Quiet Operations