Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

Blog | October 28th, 2025

Wildon Engineering delivers Kemel Air Seal retrofits for leak-free stern tube seals, reducing lube-oil risk and enhancing vessel performance and efficiency.

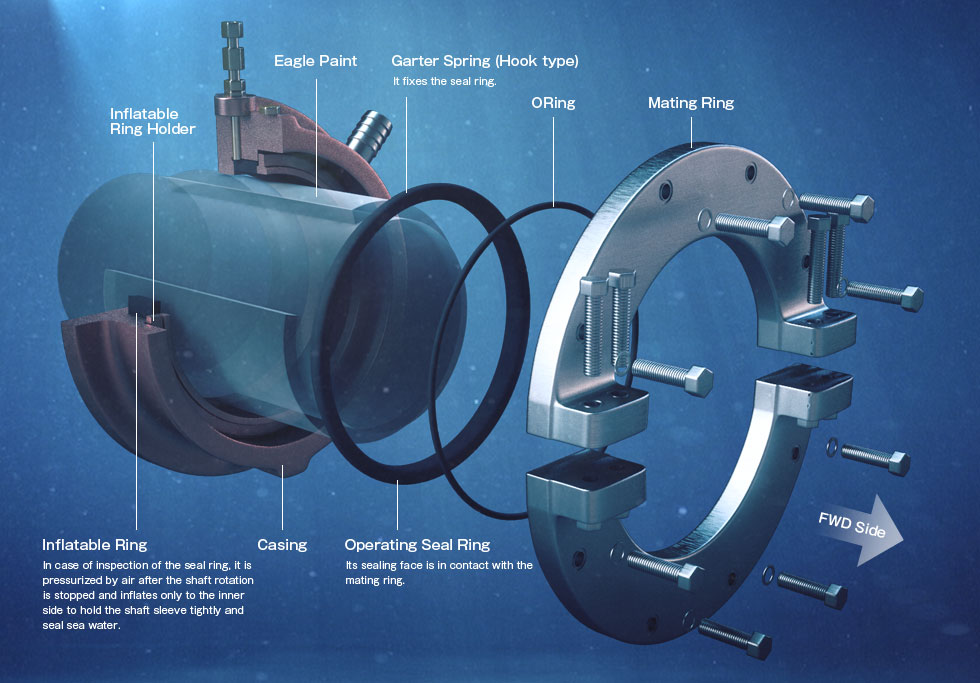

Stern tube seals are vital in vessel propulsion systems, creating a barrier between seawater and the lubricating oil inside the stern tube. While this barrier protects propulsion components and prevents environmental risks, traditional seals are often prone to leaks that raise maintenance costs and pollution risks. Kemel Air Seal retrofits provide a reliable, eco-friendly solution, ensuring leak-free performance and greatly reducing lube-oil risk.

What Are Kemel Air Seals?

Kemel Air Seals are advanced marine sealing systems designed to prevent both oil leakage from the stern tube and water ingress into it. They use a pressurised air barrier to prevent seawater and lubricating oil from mixing, stopping oil leaks and protecting bearings from water intrusion.

Kemel, a globally recognised marine seal manufacturer, has developed these systems to align with stringent environmental regulations and the operational demands of modern fleets. As such, these retrofits are a trusted choice for ship owners seeking enhanced reliability, sustainability, and operational performance.

The Operational and Environmental Gains of Kemel Air Seal Retrofits

Retrofitting existing vessels with Kemel Air Seals provides a range of operational, environmental, and financial benefits. These improvements contribute to safer, cleaner, and more efficient maritime operations.

• Leak-free Operation – Kemel Air Seals eliminate oil leakage by maintaining a constant air barrier, preventing any oil from escaping into the marine environment. This technology prevents ocean contamination while ensuring compliance with international pollution standards.

• Reduced Lube-oil Consumption – By preventing oil leaks, these systems significantly reduce the amount of lubricating oil required for operation. This leads to lower running costs, more efficient resource use, and a smaller environmental footprint.

• Extended Bearing Life – With no water ingress and minimal seal wear, the bearings within the stern tube experience reduced friction and wear. This prolongs their service life, reducing the frequency of costly replacements and unplanned downtime.

• Minimal Maintenance and Downtime – These are designed for durability and ease of maintenance. Reduced seal wear lowers maintenance needs, keeping vessels operational for longer without disruption.

• Regulatory Compliance – These retrofits support compliance with MARPOL and other international environmental regulations. By preventing oil discharge, operators meet environmental standards and avoid pollution penalties.

Cost Efficiency and ROI Analysis

Investing in Kemel Air Seal delivers long-term financial advantages by lowering operational costs and enhancing vessel reliability. The improved sealing performance and reduced oil use directly translate into a strong return on investment.

Ship operators can expect the following benefits:

• Long-term operational savings from reduced oil use and fewer repairs

• Avoidance of fines or penalties from oil pollution

• Improved vessel availability and uptime

Kemel Air Seal Retrofits: A Sustainable Step Forward

Kemel Air Seal retrofits provide a reliable solution to prevent oil leaks, protect propulsion parts, and ensure environmental compliance. By retrofitting vessels with this advanced sealing technology, operators can achieve cleaner operations, lower running costs, and enhanced operational reliability.

Proactive upgrades today can prevent costly leaks tomorrow. For expert advice, feasibility assessments, or a tailored retrofit solution, contact us at Wildon Engineering — your trusted partner for high-performance marine sealing systems.

Related Blog Articles:

Water-Lubricated Stern Tube Bearings Explained: How EVR Technology Supports Marine Propulsion

Stern Tube Seals: Preventing Leaks & Maintaining Vessel Integrity

Optimized by NetwizardSEO.com.au

Recent Posts

- MESON Marine Valves: A Selection Guide by System (Bilge, Ballast, Fuel & Cooling)

- Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems