KEMEL Stern Tube Seals: Amplifying Engine Propulsion and Propeller Shaft Longevity

Blog | August 13th, 2024

Discover how KEMEL Stern Tube Seals enhance engine propulsion and extend propeller shaft lifespan. Ensure optimal performance with Wildon Engineering.

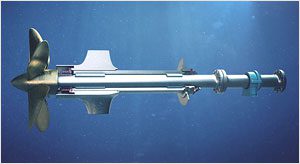

KEMEL Stern Tube Seals represent a pinnacle of innovation in marine engineering. As the largest manufacturer of seals for the marine market, KEMEL focuses on delivering high-quality solutions that not only enhance the performance of vessels but also protect the environment. These seals are essential components in the propulsion systems of ships, ensuring that the interface between the propeller shaft and the hull remains watertight and efficient.

Enhancing Engine Propulsion

The primary function of stern tube seals is to prevent water ingress and oil leakage in the stern tube, a critical component that houses the propeller shaft. By maintaining an optimal seal, KEMEL Stern Tube Seals ensure that the propulsion system operates smoothly and efficiently. This seamless operation translates to enhanced engine propulsion, allowing marine vessels to achieve better performance and fuel efficiency.

KEMEL Stern Tube Seals are designed with advanced materials and engineering techniques that provide superior durability and resistance to wear. This durability means that vessels can operate for longer periods without the need for frequent maintenance or seal replacements, which is a significant advantage for operators seeking to maximise uptime and reduce operating costs.

Propeller Shaft Longevity

The propeller shaft is a vital part of a vessel’s propulsion system, transmitting power from the engine to the propeller. The longevity of the propeller shaft is directly influenced by the quality of the stern tube seals. Poorly designed or low-quality seals can lead to shaft misalignment, increased friction, and eventual damage, all of which can result in costly repairs and downtime.

KEMEL Stern Tube Seals are specifically engineered to mitigate these risks. Their precision fit and robust construction ensure that the propeller shaft remains perfectly aligned and free from excessive wear. This protection not only extends the life of the propeller shaft but also contributes to the overall efficiency and reliability of the vessel’s propulsion system.

Environmental Protection

KEMEL’s commitment to environmental sustainability is evident in their stern tube seal designs. The seals are crafted to minimise oil leakage, which is a common environmental concern in the marine industry. By preventing oil from escaping into the ocean, KEMEL Stern Tube Seals play a crucial role in protecting marine ecosystems and adhering to stringent environmental regulations.

KEMEL Stern Tube Seals: Essential for Modern Marine Engineering

KEMEL Stern Tube Seals are a vital component in modern marine engineering, offering significant benefits in terms of performance, longevity, and environmental protection. As the authorised distributor for KEMEL Stern Tube Seals in Australia and New Zealand, Wildon Engineering is committed to providing these high-quality solutions to enhance the maritime industry’s efficiency and sustainability. By choosing KEMEL, vessel operators can ensure their propulsion systems are not only effective but also environmentally responsible.

Optimized by NetwizardSEO.com.au

Recent Posts

- Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems

- Water Lubricated Stern Tube Bearing (EVR): Proven Technology for Smooth and Quiet Operations