KEMEL Stern Tube Seals: Applications Across Vessel Types

Blog | October 25th, 2023

Enhance maritime efficiency with KEMEL stern tube seals. Available at Wildon Engineering, boost performance across vessel types. Call us at +61 3 9555 5277.

The world of maritime engineering and shipbuilding relies heavily on precision and durability to make everything work. Among the many critical components involved, stern tube seals play a vital role in ensuring the efficient and smooth operation of vessels. One notable brand in this field is KEMEL, renowned for its innovative stern tube seals and other solutions that are widely applied and maximised across various vessel types.

A Quick Overview of Stern Tube Seals

Before delving into their applications, you must first know the fundamental function of stern tube seals. These seals are crucial elements in ships as they prevent water from entering the ship’s hull while allowing the propeller shaft to rotate smoothly. Without proper sealing, water ingress can swiftly lead to structural damage and decrease the efficiency of the vessels.

KEMEL stern tube seals have been engineered with precision and cutting-edge technology to meet the demanding requirements of the maritime industry. Their general design and materials ensure minimal friction, reduced wear and tear, and enhanced longevity.

Now, what set KEMEL stern tube seals apart is their commitment to innovation and continuous improvements. These products are designed to reduce maintenance intervals, lower operational costs, and provide peace of mind to vessel operators like you as they are made from durable materials like Viton and NBR. Moreover, the dedication of KEMEL to sustainability aligns with the global maritime industry’s efforts to reduce environmental impact.

KEMEL Stern Tube Seals: Applications

Numerous types of vessels can take advantage of KEMEL stern tube seals. Some of these marine vessels are the following.

• Cargo Ships: KEMEL stern tube seals are commonly found in cargo ships, where reliability and performance are paramount. They help maintain the integrity of the vessel’s hull and ensure smooth propulsion.

• Tankers: Tanker vessels transport liquids or gases. They heavily rely on stern tube seals to prevent pollution or leakage. KEMEL’s seals are trusted to provide a secure barrier against any potential environmental hazards.

• Passenger Ships: In the cruise and passenger ship industry, passenger safety and comfort are of utmost importance. KEMEL stern tube seals contribute to smooth and silent propulsion, enhancing the overall passenger experience.

• Fishing Vessels: Fishing vessels endure challenging conditions at sea. KEMEL seals are chosen for their ability to withstand extreme elements like heat, water impact, and many more while ensuring the vessel’s structural integrity.

• Navy and Defence Vessels: Military vessels demand top-notch reliability. KEMEL stern tube seals are trusted for their performance in naval and defence applications, where precision and durability are non-negotiable.

• Research and Exploration Vessels: Scientific research and exploration vessels, often operating in remote and sensitive ecosystems, choose KEMEL seals to minimise the risk of oil spills and environmental damage.

• Offshore Platforms: Offshore drilling and production platforms rely on specialised vessels for their operations. KEMEL stern tube seals contribute to the efficient functioning of these vessels, ensuring uninterrupted supply chains.

KEMEL stern tube seals, which can be acquired from us at Wildon Engineering, have found applications across a wide spectrum of vessel types, showcasing their adaptability, reliability, and contribution to the efficiency and safety of maritime operations. As the maritime industry continues to evolve, KEMEL remains at the forefront, ensuring marine vessels sail smoothly and securely across the world’s vast oceans.

Optimized by NetwizardSEO.com.au

Recent Posts

- Yanmar Parts Online Australia – Genuine Yanmar Spare Parts at Competitive Trade Prices

- Turbochargers Supply from Japan Marine: Wildon Engineering’s Excellence in Global Shipping

- Mitsubishi VOS Ballast Water Treatment System: Next-Generation Marine Environmental Solutions

- Yanmar Marine Compressors: Reliable Power Systems for Commercial Vessels

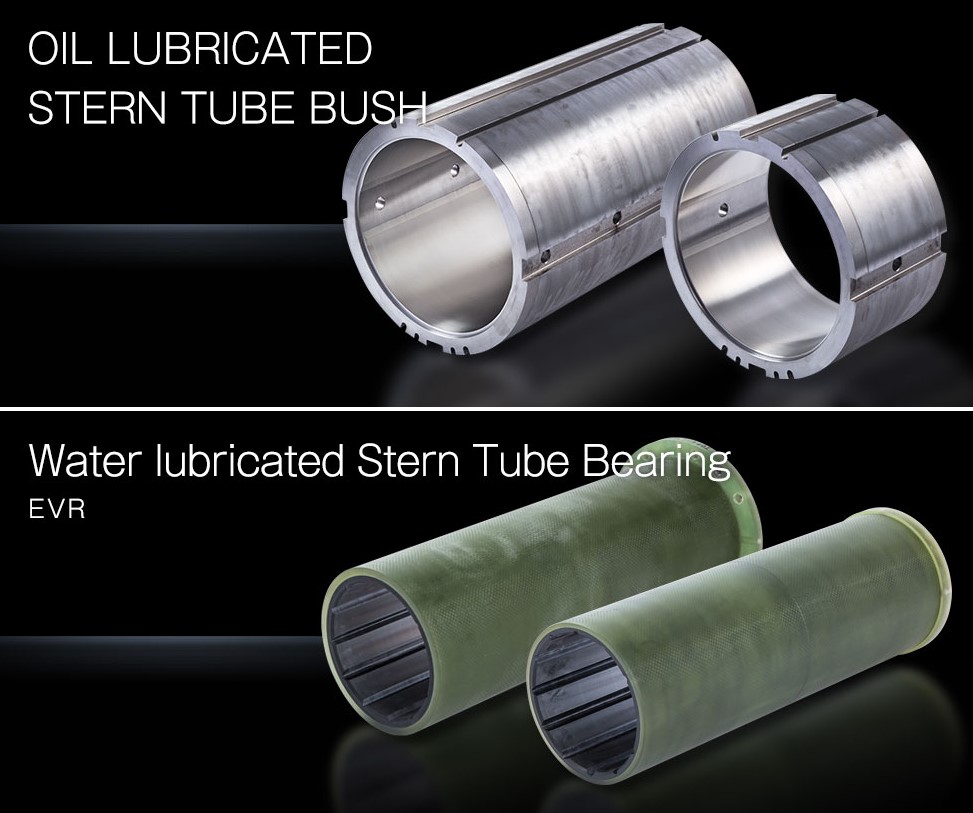

- Water-Lubricated Stern Tube Bearings Explained: How EVR Technology Supports Marine Propulsion

- YANMAR Auxiliary Generator Engine Parts for Commercial Vessels

- Fluid Control Systems: Innovations in Marine Applications

- Yanmar Diesel Generators Australian Distributor: Power for Shipping & Marine Operations

- Navigation & Communication Equipment: Essential Tools for Safe Voyages

- Stern Tube Seals: Preventing Leaks & Maintaining Vessel Integrity