KEMEL Stern Tube Seals: Functions and Applications That Are Environment Friendly

Blog | October 18th, 2016

As our oceans accumulate more lanes of traffic, a subsequent need for a reliable mechanical barrier rises to accommodate these seagoing trade ships and cruising vessels. Reliability is the watchword on the shipping lanes, for these massive liners, tankers, and freight vessels glide across the open seas while containing many potentially toxic engineering systems. KEMEL stern tube seals underscore this environmentally conscious mindset by delivering a marine sealing product that reinforces this reliability factor.

In Praise of KEMEL Stern Tube Seals

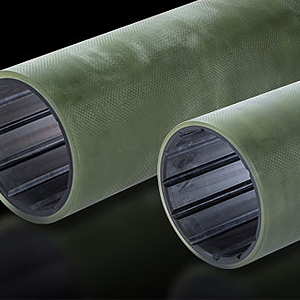

The hollow tube located at the rear end (stern) of a ship is regarded as a critical interface zone. It’s down here below the water line that power transmission mechanics induces fluid propulsion. A mammoth shaft rotates in response to the multi-storey engine, which, in turn, spins a propeller. In short, the stern tube is the bridging hollow surrounding a shaft that drives the ship through the waves, so the sealing system framing this aft tube is responsible for several crucial water-purified tasks.

Water Lubricated Shafts Cooly Propel Vessels

Superior wear life is encouraged by incorporating an ever-present lubricant. True enough, the salt or fresh water medium may not be highly viscous, but it is cold, very cold. Additionally, the inflatable seal and mating ring seals used in this KEMEL product use hydrodynamic power to keep clearance margins consistent between the shaft and the ring-to-seal assembly. In this manner, wear is reduced and power transmission is efficiently managed. Secondly, the dexterous stern tube configuration also rejects potential pollutants, as it functions as an oil barrier, thus protecting the oceans.

Determining Functions and Applications

The anti-vibration build incorporated within these sealing products stops engine vibration and shaft deviations from thwarting the fluid-isolating characteristics of this stern tube mechanism. That’s a formidable attribute considering the size of modern freight ships and oil tankers. Simply put, this item is well-suited as a large-scale water containing and fluid isolating solution, for it mates perfectly to its surroundings while handling adverse conditions. Vibrations, shaft stress, and radial shear are all accounted for by all KEMEL stern tube seals.

When viewing gargantuan vessels floating across the waves at speed, feelings of awe and intimidation are not uncommon. But these stern tube seals are never intimidated by radial stresses or water lubrication capacities. In fact, they’re designed to excel under exactly these environmental and mechanical conditions, yet they’ll never threaten that environment with a parts-fatiguing leak, again thanks to the integrity of their material build.

Optimized by NetwizardSEO.com.au

Recent Posts

- MESON Marine Valves: A Selection Guide by System (Bilge, Ballast, Fuel & Cooling)

- Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems