Mechanical Seals from Japan Marine for Safeguarding Rotating Shafts

Blog | January 22nd, 2024

Discover the role of mechanical seals from Japan Marine in safeguarding rotating shafts. Prevent leaks in maritime settings. Call us at +61 3 9555 5277.

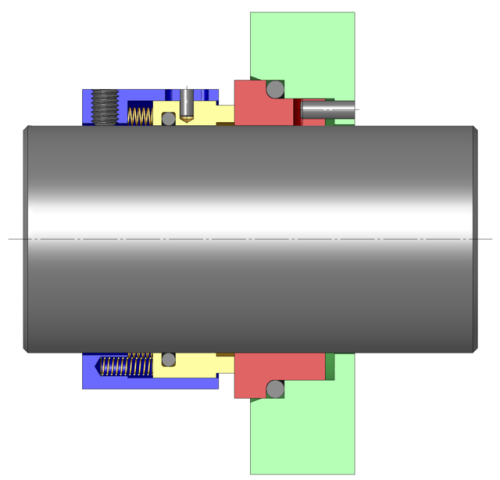

The relentless force of the sea can be taxing. Hence, owners of marine vessels must ensure their components can overcome the challenges and demands associated with modern shipping and offshore operations. One primary component that marine vessel owners like you can take advantage of is the mechanical seals. These unsung heroes can be helpful to ships and boats as they can ensure the integrity of rotating shafts in challenging maritime environments.

Marine Environment and Mechanical Seals

The marine environment poses unique challenges to machinery due to factors such as saltwater exposure, high humidity, temperature variations, and constant vibrations. In this demanding context, mechanical seals become crucial components in ensuring the reliable operation of rotating shafts in marine applications. From preventing leaks to withstanding the corrosive effects of saltwater, mechanical seals play a pivotal role in safeguarding the efficiency and longevity of marine equipment.

How to Choose the Right Mechanical Seals

When picking the right mechanical seals for your marine applications, you must consider the following.

• Corrosion Resistance: Marine machinery is constantly exposed to corrosive saltwater, which is why you should opt for mechanical seals that possess adequate corrosion resistance. Your sealing must be made from stainless steel, ceramics, or advanced polymers.

• Water Tightness: The primary function of mechanical seals in marine applications is to prevent the ingress of water into critical components. To make them useful in your vessel, you must opt for seals that can provide water-tight barriers. This quality can help protect your rotating shafts from the corrosive effects of seawater.

• Temperature and Pressure Variations: Marine environments experience dynamic temperature and pressure variations, necessitating seals that can adapt to these changing conditions. Those with excellent thermal stability must be installed to withstand fluctuations in temperature.

• Vibration Resistance: Vibration is inherent in marine operations. Hence, your seals must be resistant to the constant movement associated with waves, ship motion, and machinery operation. They can also be more effective if proper installation techniques are carried out.

Mechanical Sealing in Your Marine Vessel

Once you have opted for the right mechanical seals, you can then integrate them into various parts of your marine vessel.

First, they can be integrated into your propulsion systems. Mechanical seals play a vital part in sealing the shafts of propulsion systems, preventing seawater from entering the engine room and ensuring the efficiency of propulsion components. They can also be installed on your pump systems to seal the pump shafts, maintaining the integrity of fluid transfer systems.

If you want to make sure your marine vessels will be equipped with the right mechanical sealing, you must let experts help you with their installation. Additionally, you must ensure they will be subjected to routine inspections and timely replacements to avoid any issues along the way.

Mechanical seals can be effective in preserving the integrity of rotating shafts essential for propulsion, fluid transfer, and other maritime applications. Their resilience against corrosive saltwater, adaptability to dynamic conditions, and role in preventing leaks contribute to the reliability of marine machinery. If you want the best sealing for your marine vessels, you must get them from Japan Marine.

Optimized by NetwizardSEO.com.au

Recent Posts

- Turbochargers Supply from Japan Marine: Wildon Engineering’s Excellence in Global Shipping

- Mitsubishi VOS Ballast Water Treatment System: Next-Generation Marine Environmental Solutions

- Yanmar Marine Compressors: Reliable Power Systems for Commercial Vessels

- Water-Lubricated Stern Tube Bearings Explained: How EVR Technology Supports Marine Propulsion

- YANMAR Auxiliary Generator Engine Parts for Commercial Vessels

- Fluid Control Systems: Innovations in Marine Applications

- Yanmar Diesel Generators Australian Distributor: Power for Shipping & Marine Operations

- Navigation & Communication Equipment: Essential Tools for Safe Voyages

- Stern Tube Seals: Preventing Leaks & Maintaining Vessel Integrity

- Innovative Cathodic Protection Technologies for Maritime Industries