Stern Tube Seals for Marine Vessels: Achieve Leak-Proof Propulsion

Blog | May 10th, 2024

Ensure leak-proof propulsion for marine vessels with stern tube seals. Available at Wildon Engineering, explore their notable importance and benefits.

Stern tube seals are vital components of marine propulsion systems, responsible for preventing seawater from entering the ship’s hull and lubricating oil from leaking into the sea. These seals are located at the junction of the propeller shaft and the ship’s hull, where they create a watertight barrier that allows the shaft to rotate smoothly while keeping the surrounding environment dry. The proper functioning and quality of stern tube seals must be ensured to guarantee the safety, efficiency, and environmental compliance of marine vessels. Hence, you must get them from Wildon Engineering.

Key Roles of Stern Tube Seals

Stern tube seals generally help in maintaining the integrity and performance of marine propulsion systems. By preventing seawater ingress and oil leakage, these seals help protect the ship’s machinery from corrosion, contamination, and premature wear, ensuring safe and reliable operation in harsh marine environments. Additionally, stern tube seals contribute to environmental protection by reducing the risk of oil pollution and minimising the ecological impact of marine activities.

Compliance with stringent maritime regulations and international standards further underscores the importance of properly functioning stern tube seals in modern marine operations.

Stern Tube Seals: Operations

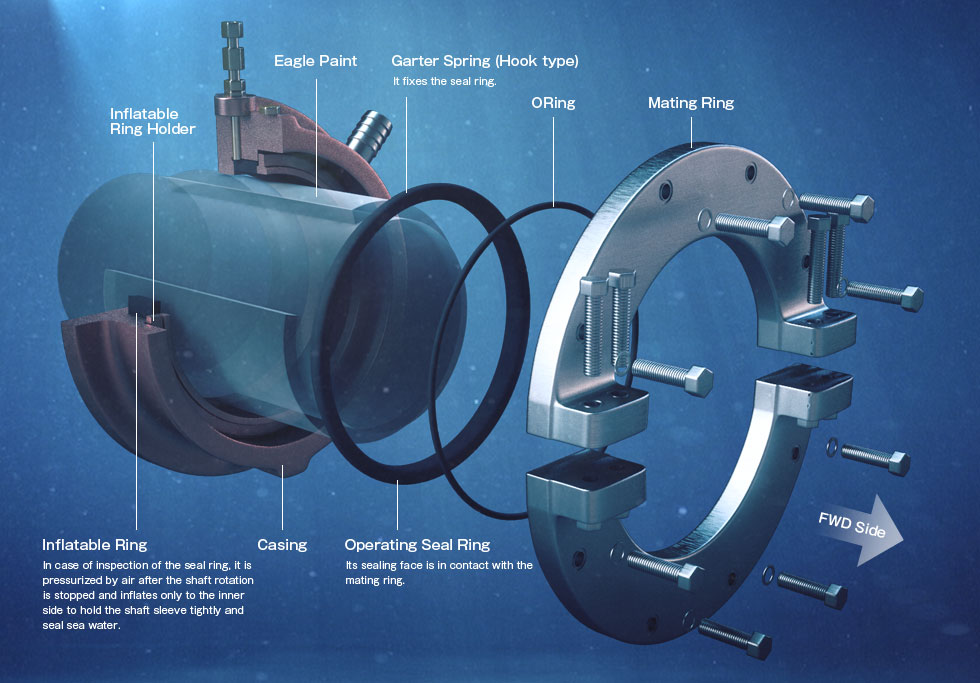

The operation of stern tube seals involves creating a watertight barrier around the propeller shaft to prevent the ingress of seawater and the egress of lubricating oil. This is achieved through the use of sealing elements, such as lip seals, mechanical seals, or inflatable seals, which are installed within the stern tube assembly. These seals are designed to withstand high pressures, temperature variations, and mechanical loads encountered during ship operations.

The choice of seal type often depends on factors such as shaft speed, operating conditions, and environmental considerations. Advanced sealing technologies, such as water-lubricated and eco-friendly seals, are increasingly being adopted to enhance performance and sustainability.

Advantages and Maintenance

The advantages of stern tube seals extend beyond preventing leaks and protecting marine machinery.

These seals help improve operational efficiency by reducing frictional losses, minimising energy consumption, and extending the service life of propulsion components. By maintaining a sealed environment around the propeller shaft, stern tube seals also contribute to smoother sailing, enhanced manoeuvrability, and reduced maintenance downtime. Furthermore, the reliability and performance of stern tube seals enhance the safety and seaworthiness of marine vessels, providing peace of mind to shipowners, operators, and crew members alike.

Now, proper maintenance and regular inspection are essential for ensuring the continued effectiveness of stern tube seals throughout the service life of a marine vessel. Routine maintenance tasks may include lubrication, cleaning, and adjustment of sealing elements, as well as monitoring of operating parameters such as temperature and pressure. Periodic inspections, conducted during scheduled dry-docking or routine surveys, help detect early signs of wear, damage, or degradation and facilitate timely repair or replacement of worn components.

Stern tube seals, which are available at Wildon Engineering, are important components of marine propulsion systems, providing leak-proof protection for propeller shafts and ensuring the safe and efficient operation of marine vessels. With proper design, operation, maintenance, and inspection, stern tube seals help optimise the performance, reliability, and sustainability of marine propulsion systems, contributing to the success and longevity of modern maritime operations.

Optimized by NetwizardSEO.com.au

Recent Posts

- Turbochargers Supply from Japan Marine: Wildon Engineering’s Excellence in Global Shipping

- Mitsubishi VOS Ballast Water Treatment System: Next-Generation Marine Environmental Solutions

- Yanmar Marine Compressors: Reliable Power Systems for Commercial Vessels

- Water-Lubricated Stern Tube Bearings Explained: How EVR Technology Supports Marine Propulsion

- YANMAR Auxiliary Generator Engine Parts for Commercial Vessels

- Fluid Control Systems: Innovations in Marine Applications

- Yanmar Diesel Generators Australian Distributor: Power for Shipping & Marine Operations

- Navigation & Communication Equipment: Essential Tools for Safe Voyages

- Stern Tube Seals: Preventing Leaks & Maintaining Vessel Integrity

- Innovative Cathodic Protection Technologies for Maritime Industries