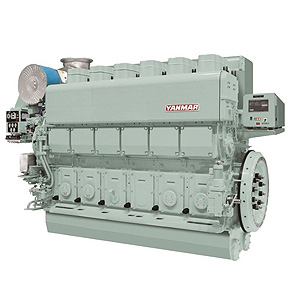

Yanmar Develops the Fuel Efficient and Durable EY33 Series for Vessels

Blog | April 28th, 2017

Marine engine design is an ever-evolving engineering craft. The goal is to build a power transmitting architecture that treats its prime moving innards as a compact powerhouse. The durable EY33 engine series is lending credence to that design goal. Built to deliver fuel-efficient propulsion, the Yanmar EY33 series is making waves, so let’s lift this potent machine onto a figurative pedestal, a place of prominence where we can point out its finest features.

A Numbers Rundown

High-pressure drive ratios are realised when the Miller-type camshaft and supercharger are coupled. We’re talking about a piston stroke length of 440mm. That cylinder-centric span pairs efficiently with a 750min-1 speed rating, a metric that becomes relevant when the EY engines are employed as a propulsion source. As for auxiliary engine applications, the 6EY33LW and 8EY33LW variants occupy this section of the newly invested marine power plant family. They’re built to generate electricity for the vessel. Meanwhile, the 6EY33W and 8EY33W are the propulsion powerhouses. The lead figures in the two models are there to differentiate cylinder configurations, which means the 6EY33W is a 6 cylinder propulsion engine.

Intelligently Designed

Fuel efficiency is a feature that’s near and dear to Yanmars’ engineering team. A number of advanced 3D simulations have been run on the machine components to optimise the drive system. It’s this optimisation process that brings out the best features of the design. Naturally, the simulated scenarios target speed and fuel sipping functions, but they also tune the cylinders, camshaft, and supercharger so that any and all NOx and CO2 emissions are significantly reduced. Essentially, the combustion characteristics of the EY33 marine engine series are shaped and profiled with the environment in mind.

Built Marine-Tough

All of the high-pressure ratios and supercharged innards need some kind of robust housing to constrain and channel the raw energy. That’s a job for the alloy steel pistons and the CPC coated piston rings. After all, there are no roads or sharp turns, stop signals or junctions out on the open waves, just the open water and its moody temper. That’s why these alloys and coatings offset long-term issues, like cylinder abrasion and part’s seizure events. The frictionless materials and finishes keep the engine cycling, reduce maintenance, and increase material durability.

The specifications for a new marine powerhouse are subject to some stringent regulations, including a number of environmentally-oriented guidelines. The Yanmar EY33 marine engine series has introduced a number of 6 and 8-cylinder power plants that easily satisfy these internationally established regulations. More than this, though, the engines cut harmful emissions, improve fuel efficiency, and add superior, environmentally-biased performance to any vessel.

Source: http://www.yanmarmarine.eu/News-detail/yanmar-develops…

Optimized by NetwizardSEO.com.au

Recent Posts

- Yanmar Parts Online Australia – Genuine Yanmar Spare Parts at Competitive Trade Prices

- Turbochargers Supply from Japan Marine: Wildon Engineering’s Excellence in Global Shipping

- Mitsubishi VOS Ballast Water Treatment System: Next-Generation Marine Environmental Solutions

- Yanmar Marine Compressors: Reliable Power Systems for Commercial Vessels

- Water-Lubricated Stern Tube Bearings Explained: How EVR Technology Supports Marine Propulsion

- YANMAR Auxiliary Generator Engine Parts for Commercial Vessels

- Fluid Control Systems: Innovations in Marine Applications

- Yanmar Diesel Generators Australian Distributor: Power for Shipping & Marine Operations

- Navigation & Communication Equipment: Essential Tools for Safe Voyages

- Stern Tube Seals: Preventing Leaks & Maintaining Vessel Integrity