Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

Blog | December 10th, 2025

Ensure reliable power in remote sites with Wildon Engineering. Discover how to maintain Yanmar diesel generators through planned and predictive strategies.

Across Australia’s remote regions, industries such as mining, telecommunications, agriculture, and off-grid facilities depend on Yanmar diesel generators for reliable power. Operating under harsh conditions like heat, dust, and limited accessibility demands robust maintenance practices. Choosing between planned and predictive maintenance is essential to minimise downtime, optimise costs, and ensure consistent performance in remote operations.

Understanding Yanmar Diesel Generators in Remote Operations

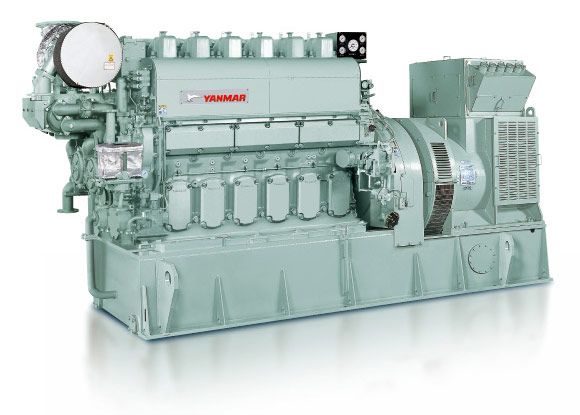

Yanmar diesel generators are widely recognised for their exceptional reliability, fuel efficiency, and durability, making them a preferred choice for operations in Australia’s demanding environments. These generators are designed to perform efficiently even under continuous load, ensuring uninterrupted power for critical operations such as mine sites, communication networks, and emergency backup systems.

Operating in remote locations presents unique challenges, as limited accessibility can delay maintenance and extend downtime during unexpected failures. Proactive maintenance, whether planned or predictive, maximises uptime, reduces repair costs, and ensures compliance with Australian standards. Wildon Engineering supplies Yanmar generators built for reliable performance in the toughest conditions.

Planned vs Predictive Maintenance

Planned and predictive maintenance are both essential for generator reliability. Planned maintenance follows scheduled servicing, while predictive maintenance uses real-time data to detect issues early. The table below highlights their key differences for remote operations.

| Aspect | Planned Maintenance | Predictive Maintenance |

| Definition | Scheduled servicing at fixed intervals based on running hours or time periods. | Maintenance decisions are based on actual equipment condition data collected from sensors and monitoring systems. |

| Approach | Preventive and routine tasks include oil changes, filter replacements, and inspections. | Data-driven; uses temperature, vibration, and performance analytics to predict component wear or failure. |

| Advantages | Simple to implement; ensures compliance with the manufacturer’s service schedule. | Minimises unplanned downtime; reduces unnecessary part replacements; enables remote monitoring. |

| Limitations | May lead to over-servicing or unexpected failures between intervals. | Requires investment in monitoring technology and skilled analysis. |

| Best Use Case | Sites with limited digital infrastructure or predictable operational hours. | High-value remote operations where downtime or access costs are high. |

How to Choose the Right Strategy for Your Site

Choosing between planned and predictive maintenance for Yanmar generators requires evaluating several critical factors. Each operation is unique, and the right strategy ensures reliability, safety, and cost-effectiveness.

• Assess Operational Environment – Remote Australian sites face dust, heat, and fluctuating fuel quality. Planned maintenance suits stable conditions, while predictive systems offer better protection when climate or usage is unpredictable.

• Evaluate Accessibility and Downtime Costs – For hard-to-access sites or those with costly downtime, predictive maintenance is the better option. Real-time monitoring detects early issues and helps prevent long outages.

• Budget and Technological Readiness – Planned maintenance is cost-effective and easy to manage for small operations, while predictive maintenance needs monitoring technology but delivers long-term savings through fewer failures and optimised servicing.

• Integrate a Hybrid Approach – Many operators in remote Australia benefit from combining both strategies. Scheduled servicing meets manufacturer requirements, while predictive tools like fuel sensors and vibration monitoring improve reliability and performance.

Ensure Continuous Power Supply with Wildon Engineering

Efficient maintenance of Yanmar diesel generators is vital for reliable power across remote Australian operations. Wildon Engineering provides tailored planned or predictive maintenance solutions to enhance performance and extend equipment life. With expert engineering and premium products, our team ensures a dependable energy supply and lasting operational resilience.

Contact us for expert maintenance strategies or explore our full range of Yanmar generators and power solutions.

Related Blog Articles:

Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems

Authorised YANMAR Parts Supplier in Australia – Genuine Components Guaranteed

Optimized by NetwizardSEO.com.au

Recent Posts

- MESON Marine Valves: A Selection Guide by System (Bilge, Ballast, Fuel & Cooling)

- Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems