Yanmar Fuel Injection Valves: The Power of Precision in Marine Engine Performance

Blog | June 27th, 2024

Learn about the importance of Yanmar fuel injection valves in marine engine performance and how they contribute to the overall reliability of YANMAR engines.

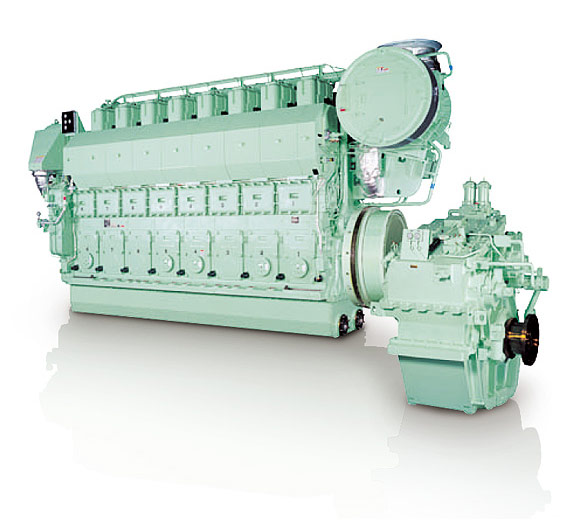

For commercial vessel operators, engine performance is paramount. Fuel efficiency, reliability, and minimal emissions are all crucial factors that contribute to smooth sailing and successful voyages. At the very core of these concerns lies a critical component: Yanmar fuel injection valves.

Key Features of Yanmar Fuel Injection Valves

Yanmar fuel injection valves are designed with several key features that contribute to their exceptional performance:

Precise Fuel Injection – Yanmar fuel injection valves are designed to deliver fuel to the engine’s cylinders with precision, ensuring optimal combustion and maximum power output.

High-Pressure Operation – These valves operate at high pressures, allowing for efficient fuel injection and precise control over the combustion process.

Robust Construction – Yanmar fuel injection valves are built to withstand the harsh marine environment, ensuring reliability and durability in even the most demanding conditions.

Easy Maintenance – The design of Yanmar fuel injection valves makes maintenance easy, reducing downtime and increasing overall efficiency.

The Role of Yanmar Fuel Injection Valves

Yanmar fuel injection valves are precision-engineered marvels that play a vital role in optimising your engine’s performance. These valves are responsible for delivering the exact amount of atomised fuel into each engine cylinder at the precise moment. This controlled injection process ensures:

• Optimal combustion: A fine mist of fuel ensures complete combustion, minimising wasted fuel and maximising engine efficiency.

• Reduced emissions: Precise fuel delivery helps to control the air-fuel mixture, leading to lower emissions that comply with stringent environmental regulations.

• Enhanced engine life: Accurate fuel metering reduces stress on the engine components, promoting longevity and reducing maintenance costs.

Maintaining Your Yanmar Fuel Injection Valves

To ensure your Yanmar fuel injection valves continue to deliver peak performance, a regular maintenance schedule is crucial. This includes:

• Periodic cleaning: Regular cleaning helps to prevent contaminants from accumulating and affecting injector operation.

• Inspection: Scheduled inspections by a qualified technician can identify potential issues before they escalate into major problems.

• Replacement: Over time, even the most durable valves will wear. Using genuine Yanmar replacement parts ensures continued optimal performance.

By prioritising genuine Yanmar fuel injection valves and a proactive maintenance strategy, you’re investing in the smooth, efficient operation of your vessel’s engine – a critical factor for success in the maritime industry.

Wildon Engineering – Your Partner in Peak Marine Engine Performance

Yanmar fuel injection valves are a critical component of YANMAR marine diesel engines, ensuring optimal performance, efficiency, and reliability. By choosing high-quality Yanmar fuel injection valves, you can ensure the continued operation of your engine and minimise downtime.

At Wildon Engineering, trading as Japan Marine Engineering Co, we are committed to providing the best YANMAR spare parts and technical support to ensure the optimal performance of your marine engine. Contact us today to discuss your Yanmar fuel injection valve requirements and ensure your engines continue to deliver the power of precision.

Optimized by NetwizardSEO.com.au

Recent Posts

- Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems

- Water Lubricated Stern Tube Bearing (EVR): Proven Technology for Smooth and Quiet Operations