Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

Blog | February 9th, 2026

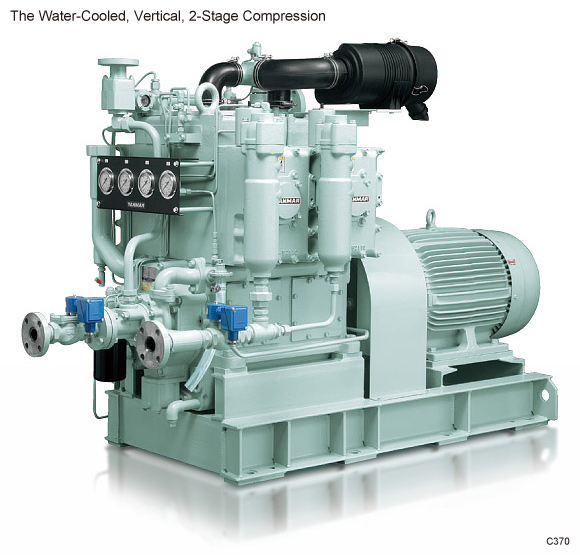

Compressed air systems are essential to the safe and efficient operation of modern marine vessels, supporting engine starts, control functions, and critical safety mechanisms. In demanding marine environments, compressed air provides a reliable and consistent power source for essential onboard systems. Yanmar marine compressors are widely trusted across Australian commercial and industrial fleets for their purpose-built design, dependable performance, and compliance with marine operational standards.

Why Yanmar Compressors Are Widely Used on Australian Commercial and Industrial Vessels

Australian marine operations face unique challenges, including long operating hours, harsh coastal conditions, and strict regulatory requirements. Yanmar compressors are engineered to meet these demands, making them a preferred choice for vessel owners, operators, and marine engineers across the country.

Their widespread use is driven by a combination of proven engineering, durability, and strong local support. Key reasons for their popularity include:

• Robust construction designed for harsh marine and saltwater environments

• Consistent performance under continuous and heavy-duty operating conditions

• Compact design suitable for confined engine room spaces

• Compatibility with a wide range of marine diesel engines

• Reliable access to genuine parts and technical support within Australia

Common Applications of Yanmar Marine Compressors

Compressed air produced by marine compressors is used across several critical onboard systems. Below are the most common applications where reliability and precision are essential.

• Engine Start Systems on Marine Diesel Engines – Marine compressors supply compressed air for engine start systems, particularly for large diesel engines that use air-start mechanisms. By charging air receivers and delivering high-pressure air during start-up, these systems ensure reliable engine starting in remote locations and during power interruptions.

• Valves, Actuators, and Control Systems – Compressed air powers pneumatic valves and actuators used in fuel management, engine control, and auxiliary systems. Pneumatic controls offer precise and reliable operation in marine environments where electrical systems may be affected by moisture or vibration, supporting efficient and dependable vessel performance.

• Safety and Emergency Systems – Safety is a critical priority in marine operations, with compressed air systems supporting emergency engine starts, safety valves, and pressure relief functions. Reliable and compliant compressed air systems are essential during dead-ship scenarios and form a vital part of onboard safety infrastructure.

Why Yanmar Marine Compressors Are Ideal for Australian Vessels

Australian marine operators require equipment that performs reliably in diverse and often challenging conditions. Yanmar marine compressors are designed with durability, efficiency, and ease of maintenance in mind. Their corrosion-resistant materials, proven engineering, and long service life make them suitable for both coastal and offshore applications.

Equally important is the availability of local expertise and support. Access to authorised service providers and genuine parts ensures reduced downtime and long-term operational confidence for Australian vessel operators.

Supporting Reliable Marine Operations with Wildon Engineering

Wildon Engineering is a trusted Australian supplier of Yanmar marine compressors, providing expert support for commercial and industrial marine applications. With a strong understanding of local operating conditions and compliance requirements, we offer reliable solutions backed by technical knowledge and genuine parts support.

Contact us for all your marine compressor requirements and discover how our services can support your operations.

Related Blog Articles:

Marine Spare Parts Australia: Genuine Components for All Vessel Types

Authorised YANMAR Parts Supplier in Australia – Genuine Components Guaranteed

Optimized by NetwizardSEO.com.au

Recent Posts

- MESON Marine Valves: A Selection Guide by System (Bilge, Ballast, Fuel & Cooling)

- Yanmar Marine Compressors: Applications in Engine Starts, Valves, and Safety Systems

- Water vs Oil in Stern Tube Bearings: The Cost & ESG Truth Shipowners Can’t Ignore

- Yanmar Turbochargers: How Correct Spec-Matching Supports Lower SFOC and Prevents Surge

- Yanmar Diesel Generators: Planned vs Predictive Maintenance Strategies for Remote Operations

- Mareflex SOLAS Marine Tapes: Safety Applications on Marine Vessels

- Yanmar Propulsion Systems: FPP vs CPP Propellers for 6EY and 6N Series Fuel Efficiency

- Mitsubishi K.K. Purifier Separator: The Key to Cleaner Fuel and Smoother Operations

- Kemel Air Seal Retrofits: Leak-Free Stern Tube Seals and Reduced Lube-Oil Risk

- Yanmar Auxiliary Generators: Sizing for Reefers, Hotel Loads, and Dynamic Positioning Systems