Marine Compressor: Factors to Consider for Seaworthy Performance

Blog | September 21st, 2023

Know the factors to consider when choosing a marine compressor. Available at Wildon Engineering, secure reliability on the high seas. Call +61 3 9555 5277.

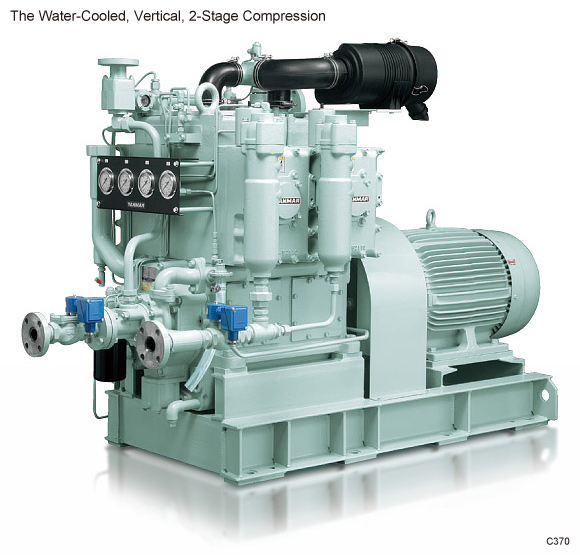

A marine compressor is a specialised type of compressor designed and built for use in maritime and marine environments. It provides compressed air for a wide range of critical marine applications, making it a vital component of onboard ships, vessels, and offshore platforms.

This specific component of the said ships and platforms helps power pneumatic tools, maintain proper pressurisation in critical systems, and so on. The presence of the compressor alone allows ships, vessels, and offshore platforms to perform optimally throughout their operations. However, operating in the harsh and demanding marine environment poses unique challenges for the compressor, which may lead to problems along the way.

If you will be replacing your marine compressor, here are some things you must consider to ensure it will perform optimally.

Corrosion Resistance

One of the primary challenges faced by marine compressors is corrosion as it often occurs due to exposure to saltwater and harsh marine environments. When selecting a marine compressor, it should be made from materials that offer high corrosion resistance. Components made from stainless steel or other corrosion-resistant materials can significantly extend the compressor’s lifespan and reduce maintenance requirements.

Size and Space Constraints

Marine vessels often have limited space and strict size constraints. Therefore, you must pick a marine compressor that is compact and can be efficiently integrated into your vessel. Compact compressors not only save valuable space but also allow for better layout and organisation of other crucial ship systems.

Capacity and Air Delivery

The capacity and air delivery rate of a marine compressor depend on the requirements of a vessel. Your compressor must be able to deliver sufficient compressed air to meet the demands of various onboard applications like air start systems, pneumatic tools, and ventilation systems. Accurate calculations of air consumption in different scenarios are crucial to ensure the compressor’s capacity aligns with the needs of your vessel.

Reliability and Redundancy

Reliability is paramount in marine operations, where the safety of the vessel and its crew depends on the proper functioning of equipment. Choosing a reliable marine compressor from reputable manufacturers can help minimise the risk of breakdowns and downtime. Additionally, incorporating redundant systems or backup compressors ensures continuous operation even in the event of a primary compressor failure.

Energy Efficiency

Energy efficiency is a critical consideration for marine compressors, as they can be significant consumers of onboard power. Opting for an energy-efficient compressor can reduce fuel consumption and lower operating costs, which makes your vessel or ship more environmentally friendly and economically viable.

Noise and Vibration Control

Noise and vibrations can be detrimental to crew comfort and the overall operation of the vessel. Selecting a marine compressor with noise and vibration control features can help maintain a more pleasant onboard environment and improve the working conditions for your crew.

A well-chosen marine compressor is essential for the seaworthy performance and efficiency of marine vessels. Considering these factors can ensure the optimal selection and operation of marine compressors. By choosing and investing in high-quality and seaworthy marine compressors from us at Wildon Engineering, you can enhance the safety, productivity, and operational efficiency of your ship or vessel, which allows for smooth and successful marine operations even in the most challenging maritime conditions.

Optimized by NetwizardSEO.com.au

Recent Posts

- Marine Anchor and Chain: Innovations in Anchor Technology for Modern Vessels

- Marine Supplies and Dry Docking: How Japan Marine Spares Improve Efficiency

- Marine Deck Cranes & Machinery Supply from Japan Marine Engineering: Navigating the Global Market in 2024

- Marine Diesel Turbochargers: New Equipment and Spares from Japan Marine Engineering

- KEMEL Stern Tube Seals: Amplifying Engine Propulsion and Propeller Shaft Longevity

- Mitsubishi Selfjectors: The Cutting-Edge Oil Purifiers for Marine Vessels

- Marine Vessel Spare Parts: Australian Global Supplier for Shipping Industries

- Yanmar Fuel Injection Valves: The Power of Precision in Marine Engine Performance

- Why Yanmar Fuel Injection Pumps are the Reliable Choice for Your Engines

- Yanmar Diesel Engine Maintenance: Advantages of Using Genuine Yanmar Parts and Fluids